|

|

|

|

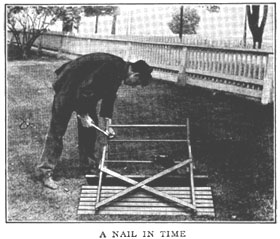

A Handy Feed Basket

ROVIDE a feed basket like this to strap upon the nose of a horse when giving the animal feed while away from the stable. It is simpler to make than the round basket, and has an added advantage. When not in use, the two sides press together and occupy scarcely any room. Cut out two semi-circular pieces of wood from a 3/4-inch board in the shape suggested in the cut. Setting them at the proper distance apart, tack a strip of canvas, or other stout cloth, around the curved partition, as shown in the accompanying picture. Nail a strap and a buckle at the sides, to go over the head, and the feed basket will be complete.

The form of this basket more nearly fits the shape of a horse's head, and besides, because of its oblong shape, gives the horse more freedom in opening his mouth than does the close-fitting round basket.

He who will not be counseled cannot be helpedMake the Horse Eat Slowly

If your horse has the habit of bolting his feed you can easily remedy it by making a self-feeder on his box. The accompanying drawing shows how a feeder may be made similar to a poultry feed hopper. The contrivance may be made of inch boards large enough to hold one feed. The horse can get the grain only in small quantities and so cannot eat it more rapidly than he should. The bottom must be made with enough slant to insure all of the feed coming out in the trough.

I am only one,

But I am one.

I cannot do everything,

But I can do something.

What I can do I ought to do;

And what I ought to do

By the grace of God I will do.Stalls Better than Stanchions

The only point in favor of stanchions is that they take up less room than stalls, but the increase in milk is a reward for allowing more space and convenience to each cow. The cut shows one kind of stall. The rack, a, is of hardwood 30 inches high, with the slats wide enough so the cow can thrust her nose through up to her eyes.

The bottom of the rack is 18 inches wide, extending into the stall toward the cow. The feed box, b, slides through an opening in the stall on the barn floor. It can be drawn into the feedway, cleansed out and a new feed put in without being disturbed by the cow. The halter strap, c, is just long enough to allow the cow to lie down comfortably. The gutter, d, is 8 inches lower than the stall floor. When she lies down she will put her head under the rack in kneeling and when she gets up, she will move backward so that she can look through the rack. The length and width of stall can be made to suit the cows. Small breeds, like Jerseys and Ayrshires, will need about 6 inches less each way than Holsteins and Shorthorns.

Knowledge is proud that he has learned so much; Wisdom is humble that he knows no more.

-- Cowper.

The man who is always poking his nose into other folks' business rarely has any of his own worth attending to.

There is no knowledge that is not power.

-- Emerson.Good Ties for Cows

The merits of stanchions and other forms of cow ties have been debated by dairymen for a long time.

The mass of experience is in favor of the tying arrangement which will give the cow the most freedom of movement. The old-fashioned solid stanchion fails in this respect. In many cases it is difficult for the cow to lie down or get up with her head fast in one of these stanchions.

The heavy swinging stanchions have advantages over this, but it also must be criticised in many cases, because of its weight and of the consequent lack of freedom on the part of the cow. A very light swinging stanchion is the best type of that form. It is easy to fasten, as the cows will in most cases put their heads in position as they go into the stall. There is not so much danger of the dairyman being struck by the horns of the cow in fastening these stanchions. Many modern barns are equipped with this kind.

The chain tie is favored in many sections. This consists simply of a crosschain with considerable slack, attached to a ring at each end which runs over a perpendicular iron rod about 18 inches long. In the center of this chain is a loop with a snap which goes around the cow's neck. This arrangement gives the greatest freedom, and allows the cow to lie down and get up without difficulty. If light partitions are used between the heads of the cows no difficulty will be experienced in their striking each other with their horns. This is by far the least expensive of cow ties, and is at the same time one of the most satisfactory.Handy Calf-feeding Device

To feed a half-dozen calves at once is entirely possible if one uses the device shown here. A man who has one reports no more trouble with calves since he has used this. He rattles a couple of buckets together, the calves come running up to the fence and soon have all their heads through the stanchions, to which they are easily fastened by throwing down lever a, which draws the bar, b, into position. Then one may feed each calf without difficulty.

Leave a 4-inch space for the calves' heads. Make the rack of 1-inch lumber and it can be moved from one pasture to another and attached to the fence or a couple of posts. It can also be used for holding ewes at lambing time.Management of Kicking Cows

Make a slatted stall just high enough so the cow can't jump out, and wide enough to hold her comfortably, with nothing to spare, and narrower at the end, where her feed box should be placed as high from the ground as is comfortable for her to eat out of. This slatted stall should be long enough to have cleats through which a bar or two should be run behind the cow to keep her from backing out, and also places to run a bar in front of her hind legs about the hock joint, or as high up as possible so as not to interfere with milking. A hole about 18 or 20 inches wide is left open for this purpose from the ground up to the cow's flank, which allows easy and safe access to the udder, while the cleat and post prevent the cow from kicking outwardly at the milker, thus insuring safety.

A Handy Milking Stool

Milkers who have trouble with restless cows that invariably either upset the pail or get a quantity of dirt in it will find the stool shown here a remedy for their troubles. It is also very serviceable in fly time. The upright pieces forming the legs and ends of stools are made of 2 x 8-inch pieces about 1 foot long. The supports for the bucket and the seat are made of inch boards. To secure rigidity it is well to put three-cornered blocks under the seat and bucket board as brace stays. The most restless cow is not likely to upset the bucket from this stool.The Ever Ready Stool

A very convenient stool for use in milking the cow in yard or field is shown in the cut. It is merely a one-legged stool to which are attached four straps connecting with a broad strap that is buckled around the waist. The stool is quickly fastened to the milker and is always in a position so one can sit down anywhere. Such a stool with a short leg would also be useful in the garden. Of course, if one preferred four legs instead of one, the stool could be so made, but experience proves that the one-legged kind serves well.Cheap Milking Stool

A cheap and very useful milking stool is made of the reel from which barbed wire has been removed. Saw off the ends so it will set level and cut a board to fit on top. Make a hand hole through the board as shown in the illustration and the stool is ready for use.Keep Stools Clean

Much milk contamination is undoubtedly due to the careless handling of the milk stools. When the milker is through milking one cow he gives the stool a toss, then he picks it up again when he starts to milk the next cow and his hands become more or less contaminated from the stool and from them the dirt drops into the milk pail during the milking.

When the milking is over, the stool is left in the yard or on the barn floor. It is so easy to make a small rack and to bore holes in the legs of the stool, so that they may be hung up. This keeps them out of the dirt and it is only necessary to brush them off carefully once in a while to keep them scrupulously clean.

The man who is constantly changing his mind usually has little to change.A Useful Stock Cart

Here is a handy transfer cart, made with wheels and cross-arch of an old corn plow to carry a hog or sheep, pigs or a calf. Raise the tongue, which lets the rear end on ground, then drive in the animal, shut the gate, pull tongue down and you have your load ready to fasten to a wagon.How to Stake out Stock

A convenient and simple contrivance so that no harm can come to the animal is to drive two stakes several feet apart and stretch a rope or wire on which a ring is placed. To this ring fasten halter strap. The animal can graze up and down on both sides without tangle or injury. The ring slides, and the stretched wire will give some.Feed Box for Field

A handy feed box for use in open lots or when steers are being fed upon grass is shown in the cut. Cut a barrel in two and strengthen the halves by placing a frame of two boards across the inside, as shown in this sketch. This will prevent the tub being smashed and will allow four animals to eat out of the trough without bothering each other unnecessarily. It is important that a very strong barrel be selected and that the hoops be nailed to each stave.

Be advis'd;

Heat not a furnace for your foe so hot

That it do singe yourself: we may outrun,

By violent swiftness, that which we run at,

And lose by over-running.

-- Henry VIII.

Have more than thou showest,

Speak less than thou knowest,

Lend less than thou owest,

Ride more than thou goest,

Learn more than thou trowest,

Set less than thou throwest.

-- King Lear.

Use or practice of a thing is the best master.Cheap Sheds of Straw

It would pay every farmer to put up in the pastures some kind of protection for his sheep, hogs and cattle. Where labor is scarce and hay and straw is plentiful and cheap, a condition which prevails in many large sections, straw sheds and barns are very profitable. Put up a framework of posts 8 feet high, 16 feet wide and as long as needed; 30 feet is a good length.

The posts are hewed evenly on two sides and set so that a bale of straw will fit snugly between them. They are cut off at a uniform height and a 2 x 6 spiked securely on top. Rafters are nailed to this and covered loosely with poles. Baled straw is used for the sides.

After the sides are up the roof is covered 2 feet deep with loose straw held in place with a few poles that are tied together in pairs and placed over the ridge. Several of these sheds have been built for five years and have not needed any attention.

Life is made up not of great sacrifices or duties, but of little things, in which smiles and kindness, and small obligations given habitually, are what win and preserve the heart and secure comfort.

-- Sir H. Davy.

You must cut your coat according to your cloth.Feed Trough for Sheep

For a sheep trough procure two 6-inch boards, a, about 3 feet long and at the bottom of each fasten another board, b. Make a flat trough and let the ends project above the top. Bore a hole through each end and also through the standards, a, and hang the trough on bolts. After the sheep eat and leave the cobs, or if it rains, the trough can be turned bottom side up and quickly cleaned.

The luck that I believe in

Is that which comes with work,

And no one ever finds it

Who's content to wish and shirk.

The men the world calls lucky

Will tell you, every one,

That success comes, not by wishing,

But by hard work, bravely done.A Novel Feed Rack

An overhead manger, as shown in the sketch, is excellent for sheep or calves. It should hang just high enough so that they will pass under without rubbing their backs. When filled with hay from above they will eat of it at their pleasure, and at the same time it will not take up floor space.

Such a manger is not suitable for grains or fine cut fodders, as too much may be wasted.

He's a city chap now, but when he comes home, he proves that his early training has not been forgotten. Teach your boy to use tools and use them right.

A Wheelbarrow Sheep Trough

It very often happens that one wishes to run the sheep on several different pastures during the season. If heavy feed racks are used it is quite a task to move them. The drawing shows a rack that can be easily moved from one field to another by one person. It is simply mounted upon a pair of wheels and has handles on the other end.

If the rack is made very large, it can be easily attached to a wagon, and thus drawn from place to place. The one shown is mounted on old cultivator wheels.Packing the Fleece

One of the best ways to pack a fleece is to lay it upon a table, turn in the head and tail, then the flanks. After this roll it up into a neat roll and tie firmly, using such a device as here illustrated.

The tying box is made from light lumber with slots, as shown, through which the rope is passed. The fleece is placed upon this rope and the roll easily tied. Wool buyers prefer to have the fleece loose, light to handle and elastic and tied up so that it can be opened if needed.Easy to Handle Heavy Hogs

The old fashion of having a lot of help around at hog-killing time is going out, owing to the use of better appliances for handling the animals after killing. You may rig up a simple arrangement so that you can handle heavy hogs without assistance. Build a fire box with a flue, b, of three joints of old stovepipe. The vat is made of heavy galvanized iron 4 feet long by 2 feet wide and 18 inches deep. Over this erect a frame of 2 x 4-inch strips, upon which place an old traveler from a hay carrier, or construct one similar to d. With the windlass arrangement, a, and the tackle, e, to which are attached the four feet of the hog, you can convey it from the vat to the bench. A rope, c, passing over the pulley at g, serves to pull the carrier, d, over the bench from the vat.Heating Water for Hog Killing

A device which is superior to the old iron kettle for heating water is shown in this sketch. Take a piece of 2-inch iron pipe 8 feet long and have it securely screwed into the bottom of a stout vinegar barrel. In the other end of the pipe screw a large wooden block.

By arranging the affair as shown in the sketch water in the barrel will be heated rapidly and can be removed as desired without bothering the fire. Do not make the mistake of putting a metal cap on the end of the pipe, or the steam may sometimes burst the piping before the cap will come off. The wooden block acts as a safety valve and will fly out if pressure is too great.A Farm Slaughterhouse

If one butchers his own stock on the farm he would do well to fix up a small building for a slaughterhouse. This can be done so easily and at such small expense that almost any farmer can afford one. It is generally most convenient to have it near the hog yard, for then the refuse can be easily conveyed to the hogs. Indeed it would not be a half bad idea to have it in some instances a part of the hog house. The room in which to kill cattle and hogs should not be less than 15 feet square. This will give plenty of space for the work. As much of the room should be kept clear from fixtures as possible.

The floor should be made of concrete graded so that it will all drain to a central opening. A pipe should carry the liquid from this opening to a trough in the hog yard. The ideal way would be to make the walls of concrete for about 3 feet from the ground. This will make it much easier to keep the place clean. It is quite necessary that a good supply of water be close at hand. If possible, a water pipe with hose attached should be in the house. This will enable one to flood the floor at any time.

The illustration shows a very good device for handling the carcasses. It is made of a heavy roller, c, 5 to 6 inches thick, and long enough to reach across the width of the room. It is supported in the middle by a bracket, d, detail of which is shown in the drawing. This makes it possible to lift a carcass of any weight. A drum, b, is attached to the roller at one end, over which is run the rope that communicates with the crank, a, at the floor. Any man handy with tools can make this derrick.

In order to simplify matters one may use a barrel cart water heater. This barrel has a valve attached at the bottom. To this is fastened a rubber hose that communicates with a small coil of pipes. This coil of pipes in turn communicates with the top of the barrel by another rubber hose. The coil of pipes is placed over a fire built in a hole in the ground, and the valve is opened.

As soon as the water in the coils becomes hot it is forced through the rubber hose, and a circulation is started. This device will heat water very rapidly and easily. When the water is heated the rubber hose is detached and the barrel wheeled under the derrick on which the hog is hung. By means of a crank the carcass is let into the water to be scalded. With simple devices one man can very easily do the butchering alone. It will be found convenient to have a table that folds up against the side of the building on which to cut up the meat.Keep Pigs out of Feed Trough

To prevent hogs crowding and getting in the trough with their feet the accompanying plan will be found practical. You can nail the Vs, or rick-rack work, on any shaped trough. They fit on a pointed or flat-bottomed trough equally well. Nail a strip lengthwise along the top of the Vs to strengthen them. Stakes driven at intervals and nailed securely to the angles will hold the Vs and trough both solid.Movable House for Breeding Sows

Individual hog houses may be constructed with four upright walls and a shed roof, as shown below. The walls and the roof are separate and can be easily taken down and replaced. These small houses can be moved about very easily. The size of the house will depend upon conditions. The construction is shown, so that any farmer with tools can easily put up one of these houses. With the individual houses the sow at farrowing time may be kept alone and away from all disturbance and there will not be too large a number of pigs in a small lot if kept in this way. The danger of spreading diseases among the animals is also reduced to a minimum where swine are kept more isolated. When properly bedded and cared for no disastrous disease need be feared. Much depends upon the sanitary conditions.Well-arranged Hog Lots

An Indiana farmer keeps his pigs in long houses which are divided into compartments opening into small lots. The sketch shows how they stand. Breeding hogs and fattening shotes are allowed the run of their own lots, as well as occasional changes into the larger field, shown at the bottom of the sketch, which is a timothy and clover pasture. It is better to have pigs in separate quarters in small bunches, for in this way they can be better attended to and the growths are more uniform.Handy Pig Catcher

Here is a homemade device for catching small pigs which saves much time and annoyance. The net may be made from a discarded lawn tennis net, the rim from a bicycle wheel, and the handle is a heavy rake handle. The net is securely fastened to the rim with some copper wire, while the rim is fastened to the handle with two pieces of band iron. Small pigs caught in the net will not squeal and struggle as when chased around the pen and caught by one leg. The element of excitement is greatly reduced by use of the net, and some would find less fun in the net method. On the whole, however, we recommend it.

The weakest arm is strong enough that strikes with the sword of justice.

Our knowledge is the amassed thought and experience of innumerable minds.

-- Emerson.Stairs for the Barn

A lot of time is saved if one has handy stairs which can be used for throwing down hay as well as a passageway. These steps are made of light material and instead of putting on a lower step, use a block, c, and attach the stringers of the stairs to it at each end with a pin. A rope passes over the pulleys at d, to a weight, which allows the stairway to be held upright while the hay is being put down. The rope, e, is handy to pull the stairs into position.Hang Up the Lantern

Here is a good idea for hanging a lantern over the barn floor. Get two pulleys with screw stems, and screw one in beam overhead, the other at top of post. Have a bracket lower on the same post. Take a piece of small but strong cord, and at one end fasten a snap and pass the other end through the pulleys. Put your lantern on the snap and draw it high enough so it will be out of reach of forking hay, and you can see all over the barn floor. You can raise the lantern high enough to pitch hay from the top of the mow with no danger of turning the light over and burning the building and contents.

The end of the cord opposite the lantern may be fastened with a snap, or more length may be allowed for adjusting the height of the lantern, and the cord may be secured by a hitch or a few turns around a button or two spikes driven halfway in and bent over in opposite directions.Arrangement for Weighing

A homemade balance may be constructed with a joist loosely attached, so as to just balance over the rounded top of a heavy block. It will be useful in weighing hay and other bulky substances for feeding purposes. For weights, use small wooden boxes or bags of stone and sand which have been weighed on other scales. Place the required weight upon the balance and then place feed on the other end until it balances the weight, and it will be accurate enough for all ordinary purposes.

A Barn Windlass

It is easily made of iron pipe or a bar fastened to the ladder or other suitable support by means of eyebolts or stout staples, as shown at a in the drawing. It may be used for raising grain, wagon boxes and other heavy things to the upper part of the barn, and, if desired, may be rigged with block and falls, so as to increase the power without increasing the effort. A loose bolt placed in a hole will prevent unwinding. The picture shows how simple this device is. Every farmer knows how useful a barn windlass may be.Grain Box Easy to Empty

The trouble with most grain boxes is to get out the last third of the grain. Bending over the edge jackknife fashion is neither pleasant nor healthful. A box or bin may be made with half its front on hinges, so that it can be let down and all the contents scooped out without difficulty. The bin may be made from a piano box with a partition in the middle for two kinds of grain.

Leave your son a good reputation and an employment.Easily Constructed Grain Bins

Grain bins with compartments for different kinds of feed are handy in barn or stable. By procuring a number of dry-goods boxes, all of the same size and shape, and nailing them together side by side, so that they will appear as one, the bin is easily made. The cover should extend the entire length of the bin, and though leather hinges will answer, it is better to attach it with iron ones, for then, with a good staple and hasp, the contents can be kept under lock and key if desired.

A Convenient Barn Truck

No dairyman can afford to ignore that which will lighten his labor in any way whatever. Be his stable ever so conveniently constructed, he has enough to do. Hence the importance of his considering a feeding truck or car if he does not have one. Made of good lumber, the only iron about it need be the handle at each end, by which to push or pull it along the feeding alley in front of the cows which are to be fed, and the small trucks on which it is mounted. The wheels procured, any good blacksmith can make these, so that the truck is by no means difficult to construct. The box body should be about 2 feet wide, 20 inches deep and 4-1/2 feet long. Silage can be conveyed in it from the silo to the mangers very readily. If the silo is some distance away, it will save much hard work.

If little labor, little are our gaines:

Man's fortunes are according to his paines.

-- Herrick.Takes a Man's Place

In most cases it takes two men to fill a sack of grain, but by using the sack holder one man can do it alone. Make a platform, b, 20 inches square, and fasten to it a 2 x 4, c, with notches cut in. The arms, a, should be 18 inches long. Make the upright piece 3 feet long so that long bags can be handled. Some bags will require a still longer upright piece. A device that takes the place of a man or enables a man to work twice as fast as he could without it is worth while.

A wise old owl sat on an oak,

The longer he stayed the less he spoke.

The less he spoke the more he heard.

Why are not more of us like that wise old bird?

There are but two ways of paying debt: increase of industry in raising income, increase of thrift in laying out.

-- Carlyle.

If it were done, when 'tis done, then 'twere well

It were done quickly.

-- Macbeth.A Handy Bag Holder

It is constructed with two good boards 1 inch thick and 15 inches wide. The perpendicular one is 3-1/2 feet long, and the horizontal one 2 feet long. These are joined together and braced as shown in the drawing, and the hopper is attached, wedged out from the perpendicular board so the bag may wrap it all the way round. The hooks for holding the bag in place can be secured at a hardware store. As the whole affair, if composed of thoroughly seasoned lumber is light to handle, it can easily be carried to any spot where grain is to be put up.

Here is another scheme that saves time and labor and makes it possible for one man to do the work that usually requires two. This one is as good and perhaps better than any device that has been invented in the bag-holder line. In making it, an important point is to attach all parts very securely where they come together, especially the hopper and the braces. Otherwise, with hard usage the holder will get loose and break down.A Corn Husking Rack

Many who husk their corn by hand find it very tiresome to sit on the floor or ground in a cramped position. A rack made as shown in the drawing will hold two or three shocks and gives a better place for the husker to sit. Place the stalks cross-wise of the bench in front of you.A Homemade Feed Cutter

An old lawn mower can be arranged to make a fairly satisfactory straw or feed cutter. One must rig up a hopper, as shown in the sketch, and attach the mower to the lower end of it so that the straw or grain will just strike the knives where the grass usually comes into the mower. A crank and a belt arrangement makes it easy for one man to feed and turn the cutter. This is a good use for a lawn mower in the winter time when it is not working outdoors.Saw Root Cutter

Those who have cut roots in the winter time with a butcher knife or hatchet will fully appreciate something better for a root cutter. A Wisconsin farmer has found a serviceable homemade lever cutter very efficient for all roots. For hard ones, like rutabagas, it is about the best thing available. His is made out of an old hand saw, sharpened on the back, fastened by means of a bolt passing through a hole punched at the small end, and held by a guide formed of two pieces of wood secured upright, so as to have a slit for the saw to work in. This contrivance is a success, and with a little practice the roots may be cut very rapidly. See accompanying illustration. The cutter may be mounted upon the wall wherever it will be most convenient. The bench or platform should be at about the height of a common table.Homemade Cabbage Cutter

A cheap and easily made cabbage and root cutter is shown in the drawing. Take two 12-inch boards and nail them strongly together. With dividers mark around a circle, then saw out and mark in quarters. Cut four slots 7 inches long on a slant, as shown by dotted lines, so the cabbage will fall through easily. Next cut two circles 4 inches in diameter. Nail one to the large wheel on the back and leave the other loose on the shaft to act as a bearing. Make a frame to admit the wheel, leaving 2 inches clear, and just wide enough so the knives do not strike the side. Make a top over the wheel and put a hopper on the opposite side from the crank. The knives are 8 inches long and can be made from an old bucksaw and ground down sharp, with a bevel on one side. Screw these on the wheel at a slant according to the thickness the cabbage is wanted. A square hole should be cut through the center of the wheel for the shaft.

Kindle not the fire that you cannot extinguish.A Substantial Driveway

A plank driveway to the barn is usually made steep in order to save planks. It is continually wearing out and breaking. A substantial driveway with an easy grade can be made by driving down stakes close together on either side, and filling in between with stones, rubbish and earth, packing all down firmly. When full to the top, pack some earth against the outside of the stakes and sod over the sides. This driveway will form an easy rise and will prove very durable.

1. Workshop and Tools

2. The Steel Square

3. In and Around the House

3. In and Around the HousePart II

4. Barns and Stock

5. Poultry and Bees

6. Garden and Orchard

7. Field and Wood

8. Gates and Doors

9. When We Build

9. When We Build Part II

10. Worth Knowing

10. Worth Knowing Part II

Next: 5. Poultry and Bees

Back to the Table of Contents

Back to the Small Farms Library Index

Community development | Rural development

City farms | Organic gardening | Composting | Small farms | Biofuel | Solar box cookers

Trees, soil and water | Seeds of the world | Appropriate technology | Project vehicles

Home | What people are saying about us | About Handmade Projects

Projects | Internet | Schools projects | Sitemap | Site Search | Donations | Contact us