Appendices

Appendix A

Progress Made on a Tea Estate in North Bengal

By J. C. Watson

Gandrapara Tea Estate is situated on low rice-growing land south of the Himalayas and in a district which was commonly thought to be incapable of producing teas of a quality equal to those of estates situated on the Red Bank soil. The estate covers 2,796 acres, of which 1,242 acres are under tea; there are also ten acres of seed-bearing bushes. Paddy or rice land is available for the labour force, allotments for growing soya bean, vegetables, and so forth, and shajana trees grow in all the labourers' barees or garden patches. Everything possible is being done to improve and maintain the nutrition and health of the labour force and also of the labour force of to-morrow -- the children. Large sums are being well spent by the Company to maintain a healthy and contented labour force which is one of the finest assets of an estate. I have had the privilege of managing this estate for thirty years and not only has the labour force been contented, happy, and healthy, but the land itself has also improved.

There are resident on the estate a population of 2,756 souls, as well as two and a half million tea bushes, all to be maintained in a state of health. The tea plant requires a fertile soil and this means healthy crops, healthy animals, and last, but not least, healthy human beings. The following facts tell their own story: in the five years previous to the intensive application of humus the estate averaged yearly 795,801 lb. of tea or 5.09 oz. of tea per bush; since 1939 22,000 tons of humus, made in a central factory on the Indore method advocated by Sir Albert Howard, have been applied to the land and the yields during 1939-43 averaged 1,240,800 lb. of tea yearly or 7.94 oz. per bush.

It is undeniable that this humus is the storehouse of surplus water which is given back to the plant in dry periods. In this part of India droughts are sometimes very severe; in the period from October to April less than one and a half inches of rain has been registered, but the condition and health of the bushes compared with those estates treated wholly with artificial manures is remarkable. The art of cultivation consists in getting the humus to a depth m the soil where the moisture does not evaporate. The higher the fertility of the soil, the better the class of crop grown on it and the less are the effects of dry periods on the crops. The drainage system where heavy rainfall is experienced -- as much as 125 inches between May and September -- has to be in thorough working order to keep the soil in good heart, and there has yet to be found any better method of replacing the losses in the soil year after year than by heavy applications of organic matter. If the tea bushes receive a check, they are immediately liable to disease.

It was, therefore, essential that before starting on heavy applications of humus the drainage system be put and kept in good working order, also good shade trees were established giving a heavy leaf fall. There is no substitute for organic matter or humus in the soil. It is interesting to note that in 1943 a severe hail storm stripped the bushes and did damage estimated at 96,000 lb. of tea, but, after resting, the bushes had the stamina to ensure a rapid return to normal and a record crop was harvested.

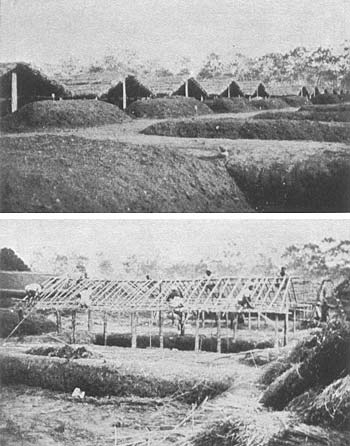

In 1934 the manufacture of humus on a small scale was instituted according to the Indore method advocated by Sir Albert Howard. The humus is manufactured from the waste products of the tea estates. All available vegetable matter of every description, such as Ageratum, weeds, thatch, leaves, and so forth, is carefully collected and stacked, put into pits in layers, sprinkled with urinated earth to which a handful of wood ashes has been added, and then covered with a layer of broken up dung and soiled bedding, after which the contents are watered with a fine spray -- not too much water, but well moistened. This charging process is continued till the pit is full to a depth of from three to four feet, each layer being watered with a fine spray as before (Plates VIII and IX).

Plate VIII. Composting at Gandrapara. Above -- Covered and uncovered pits; Below -- Roofing a pit.

|

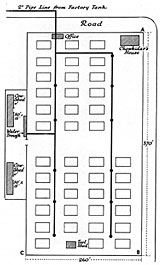

To do all this it was found necessary to have a central factory, so that the work could be controlled and the cost kept as low as possible. Details of the central factory which was erected are given in the plan (Plate XI). There are 41 pits each 31 x 15 x 3 feet deep; the roofs over these pits are 33 x 17 feet, space between sheds 12 feet, and between lines of sheds 30 feet, and between sheds and fencing 30 feet. This allows materials to be carted direct to the pits and also leaves room for finished material. Water has been laid on -- a two-inch pipe with one-inch standards and hydrants 54 feet apart, allowing the hose to reach all pits. A fine spreader-jet is used; rain-sprinklers are also employed with a fine spray. The communal cowsheds are situated adjacent to the humus factory and are 50 x 15 feet each, and can accommodate 200 head of cattle. The enclosure, 173 x 57 feet, is also used to provide outside sleeping accommodation. There is a water trough, 11 feet 6 inches by 3 feet wide, to provide water for the animals at all times. The living houses of the cow herds are near to the site. An office, store, and chowkidar's house are in the factory enclosure. The main cart-road to the lines runs parallel with the enclosure and during the cold weather all traffic to and from the lines passes over this road, where material that requires to be broken down is laid and changed daily as required. Water for the factory has a good head and is plentiful, the main cock for the supply being controlled from the office on the site. All pits are numbered, and records of material used in each pit are kept, including cost; turning dates and costs, temperatures, watering, and lifting, etc., are kept in detail. Weighments are only taken when the humus is applied, so as to ascertain tasks and tons per acre of application to mature tea, nurseries, tung barees, seed-bearing bushes, or weak plants.

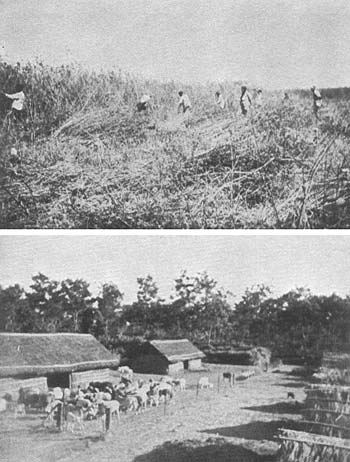

Plate IX. Composting at Gandrapara. Above -- Cutting ageratum; Below -- Communal cowsheds.

|

The communal cowsheds and enclosure are bedded with jungle and this is removed as required for the charging of the pits.

I have tried out pits with brick vents, but I consider that a few hollow bamboos placed in the pits give a better aeration, and these vents make it possible to increase the output per pit, as the fermenting mass can be made four to five feet deep.

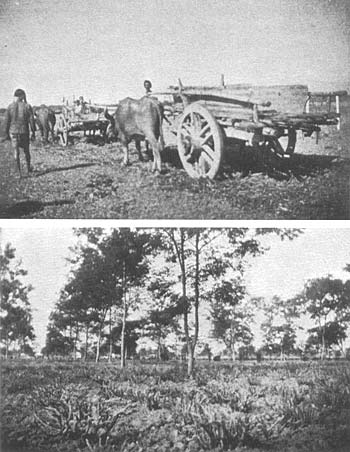

Much care has to be taken at the charging of the pits so that no trampling takes place and a large board across the pits avoids the possibility of coolies pressing down the material when charging. At the first turn all woody material that has not broken down by carts passing over it is chopped by a sharp hoe, thus ensuring that full fermentation may act, and fungous growth is general.

Plate X. Composting at Gandrapara. Above -- Crushing woody material by road traffic; Below -- Sheet composting of tea prunings.

|

With the arrangement of the humus factory compost can be made at any time of the year, the normal process taking about three months. With the central factory much better supervision can be given and a better class of humus is made. That made outside and alongside the raw material and left for the rains to break down acts quite well, but the finished product is not nearly so good. It therefore pays to cut and wither the material and transport it to the central factory as far as possible.

In the cold weather a great deal of sheet-composting is being done. After pruning, the humus is applied at the rate of seven to ten tons to the acre and hoed in with the prunings, the bulk of which varies. In this way excellent results have been obtained. The pits become small composting chambers; the roots of the tea bushes soon invade the pits, and results speak for themselves.

Plate XI. Plan of the Compost Factory Gandrapara Tea Estate

|

Full-sized image

On many gardens the supply of available cow-dung and green material is nothing like enough for requirements. Many agriculturists try to make up the shortage by such expedients as the hoeing in of green crops and the use of shade trees or any decaying vegetable matter that may be obtainable; on practically all gardens some use is made of all forms of organic materials and fertility is kept up by these means. It is significant to note that for many years now manufacturers who specialize in compound manures usually make a range of special fertilizers that contain an appreciable percentage of humus. The importance of supplying soils with the humus they need is obvious. I have not space to consider the important question of facilitating the work of the soil bacteria, but it has to be acknowledged that a supply of available humus is essential to their well- being and beneficial activities. Without the beneficial soil bacteria there could be no growth and it follows that, however correctly we may use chemical fertilizers according to some theoretical standard, if there is not in the soil a supply of available humus, there will be disappointing crops, weak bushes, blighted and diseased frames. It would, moreover, be to the good if every means whereby humus could be supplied to the soil in a practical and economical way could receive the sympathetic attention of those who, at the present time, mould agricultural opinion.

To the above must be added the aeration of the soil by shade and drainage. I am afraid many planters and estates do not fully understand this most important operation in the cultivation of the tea bush. To maintain fertility we must have good drainage, shade trees, and tillage of various descriptions to kill weeds. The best areas are the cleanest, and not only do they secure bigger crops and higher quality, but they have nothing to waste.

Humus is essential: artificials are a tonic, but humus is a food. It is not difficult to understand that the use of artificials in feeding the plant direct sidetracks a portion of Nature's essential round. Artificial stimulus, applied year after year and at the same times, must inevitably breed evils, the full extent of which are yet but dimly seen. The time may come when yield will depend entirely on quality, but quality can never under any circumstances depend upon yield. Factory-made manure is the weak link in the chain of agricultural economics. Humus is the real food of the soil and the crop; it leads to and maintains larger crops and improved quality.

For the past five years no chemical manures or sprays for the control of disease and pests have been used. The return to the soil of all organic waste in a natural cycle is considered by many scientists to be the means of obtaining the best teas and of resisting pests and disease. The tea bush requires nutrition, and Sir Albert Howard not only wants to increase the quality of human food, but, in order that it may be of proper standard, he wants to improve the quality of plant food. That is to say, he considers the fundamental problem is the improvement of the soil itself, making it healthy and fertile. "A fertile soil,' he says, 'rich in humus, needs nothing more in the way of manure: the crop requires no protection from pests: it looks after itself..." It is interesting to note that plant diseases are the consequence of infertility, so that the rational method of dealing with such problems is not to destroy the agent by means of insecticides and fungicides, but to bring the soil back into a condition of real fertility in the first instance, and then to devise the best methods to suit local conditions.

Gandrapara Tea Estate,

Banarhat P.O., Dooars.

1Oth August 1944.

Next: Appendix B. Compost Making in Rhodesia

Back to Contents

To Albert Howard review and index

Back to Small Farms Library index

Community development | Rural development

City farms | Organic gardening | Composting | Small farms | Biofuel | Solar box cookers

Trees, soil and water | Seeds of the world | Appropriate technology | Project vehicles

Home | What people are saying about us | About Handmade Projects

Projects | Internet | Schools projects | Sitemap | Site Search | Donations | Contact us