![]()

Search the Journey to Forever website – click HERE

|

Journey to Forever: Make a donation |

En español

Biocombustibles, biodiesel

Navigation

Contact usTo Keith Addison Handmade Projects |

Why quality matters

Spanish version -- Versión en español

They conducted field trials with biodiesel in collaboration with end-users and found the following injection equipment and engine problems: This is what caused problems: Corrosive acids (formic & acetic)

The Fuel Injection Equipment (FIE) Manufacturers (Delphi, Stanadyne, Denso, Bosch) issued a statement on biodiesel. They strongly support it, but they have their concerns too, and they're very involved in standards development. They had a fright in Europe in the early 90s when the introduction of low-sulfur diesel saw widespread damage to injection systems, with excessive wear and failure. The same thing happened in California. They don't want it to happen with biodiesel. These are their concerns:

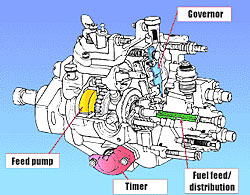

Denso Distributor Injection Pump

Free methanol in biodiesel

Effect: Corrodes aluminium & zinc, Low flash point

Failure Mode: Corrosion of fuel injection equipment

Biodiesel process chemicals

Effect: Potassium and sodium compounds, Solid particles

Failure Mode: Blocked Nozzles

Dissolved water in biodiesel

Effect: Reversion of biodiesel to fatty acid

Failure Mode: Filter Plugging

Free water in mixtures

Effect: Corrosion, Sustains bacteria, Increases the electrical conductivity of fuel

Failure Mode: Sludging, Corrosion of fuel injection equipment

Free glycerine, Mono-& di-glyceride

Effect: Corrodes non-ferrous metals, Soaks cellulose filters, Sediments on moving parts and Lacquering

Failure Mode: Filter clogging, Injector Coking

Free fatty acid

Effect: Provides an electrolyte and hastens the corrosion of zinc, Salts of organic acids, Organic compounds formed

Failure Mode: Corrosion of fuel injection equipment, Filter plugging, Sediments on parts

Higher modulus of elasticity

Effect: Increases injection pressure

Failure Mode: Potential of reduced service life

High viscosity at low temperature

Effect: Generates excessive heat locally in rotary distributor pumps, Higher stressed components

Failure Mode: Pump seizures, Early life failures, Poor nozzle sprayAgeing products

Effect: Corrodes all metallic parts

Failure Mode: Corrosion of fuel injection equipment

Higher molecular organic acids

Effect: Similar to fatty acid

Failure Mode: Similar to fatty acid

Polymerisation products

Effect: Deposits especially from fuel mixes

Failure Mode: Filter plugging, Lacquering formation in hot areas

FIEM statement in full -- Acrobat file, 104kb

Engine manufacturers have similar concerns, especially with the oxidation of biodiesel leading to a gradual increase in contamination and free water content.

The final US ASTM specification D6751 for biodiesel is based on the existing petro-diesel standard, D975, which was modified by elimination of items not applicable to biodiesel and by addition of items specific to biodiesel. A lot of work went into developing new analytical methods for a number of biodiesel properties. It's based on the hard realities of what bad fuel does to motors and fuel systems.

The German draft standard DIN EN 14214, "Automotive fuels - Fatty acid methyl esters (FAME) for diesel engines - Requirements and test methods", is one of the most complete biodiesel specifications.

The EU CEN technical committee TC19 is evolving European Standards and is liaising with the International Standards Organisation committee TC28 regarding an eventual world-wide standard.

They're not just bumbling around. There's a huge increase in diesel use, very rapid advances in diesel technology, stringent requirements in improving diesel emissions, tremendous growth in biodiesel production. They're dealing with billions and billions of dollars, with entire transport systems.

We homebrewers can do whatever we like, but it's quite possible for a homebrewer to make standard-spec fuel, in fact it's easy, so why not do it?

-- Keith Addison, message to the Biofuel mailing list, December 11, 2002 -- with thanks to DieselNet/Ecopoint Inc.

http://www.dieselnet.com/

See: National standards for biodiesel

Back to:

Biodiesel and your vehicle

Biofuels

En español -- Biocombustibles, biodiesel

Biofuels Library

Biofuels supplies and suppliers

Biodiesel

Make your own biodiesel

Mike Pelly's recipe

Two-stage biodiesel process

FOOLPROOF biodiesel process

Biodiesel processors

Biodiesel in Hong Kong

Nitrogen Oxide emissions

Glycerine

Biodiesel resources on the Web

Do diesels have a future?

Vegetable oil yields and characteristics

Washing

Biodiesel and your vehicle

Food or fuel?

Straight vegetable oil as diesel fuel

Ethanol

Ethanol resources on the Web

Is ethanol energy-efficient?