Michael Allen

Michael Allen

Tamarisk Technology

Visiting Professor, Prince of Songkla University, Thailand

The 'Deepthort' Reactor

The Specification

The Cost

The Process

The Design of 'Deepthort'

Operation of 'Deepthort' as an Oil Dryer

Operation of "Deepthort" as an Acid Catalysed Esterifier

Operation of 'Deepthort' as a Transesterifier

Operation of 'Deepthort' as a Washer

Recovering Methanol Using 'Deepthort'

Disclaimer

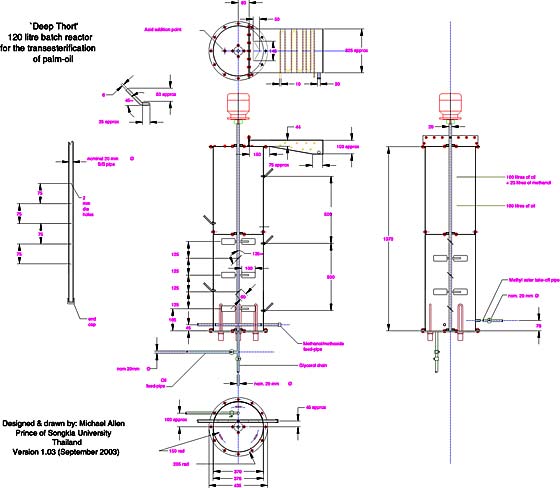

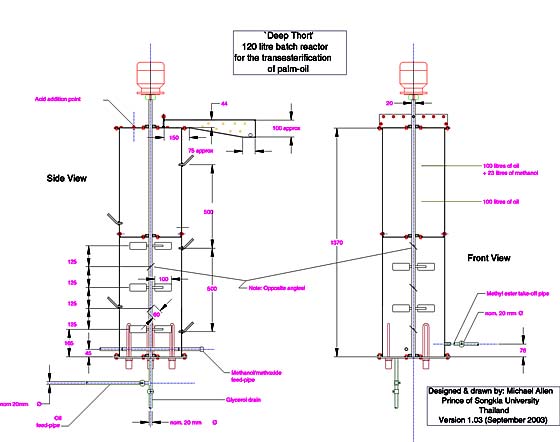

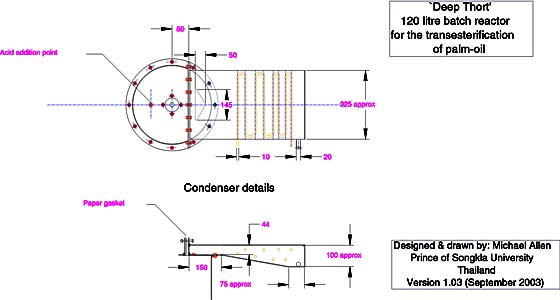

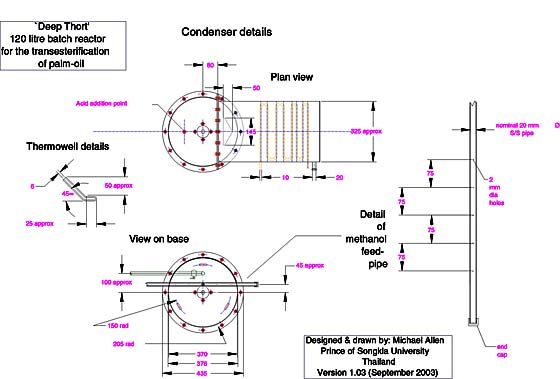

Blueprints

The 'Deepthort' Reactor

There are many forms of reactor to produce methyl esters for use as a biodiesel. Most of these make use of plastic buckets, steel drums and similar hand-me-downs. Have you ever wondered what a "purpose-built" reactor would look like?

I've called this reactor "Deepthort". Not just because a lot of thought has gone into it but also because I knew very little about "biodiesel" when I was first asked to design it. The name is my acknowledgement of the Douglas Adams's vital contribution in "The Hitchhiker's Guide to the Galaxy ". Don't Panic! seemed quite a good precept when I started out. (If you've read Douglas Adams, you'll get the connection. If you haven't ... well do!)

To my rescue came Journey to Forever and its remarkable collection of information about processes, technique and hardware connected with the processing of vegetable and animal oils to produce that golden elixir -- "biodiesel". I really feel quite privileged to have this "Deepthort" reactor put into the public domain by Keith Addison and Journey to Forever.

Front view

The Specification

Front view

Initially this was for a batch reactor to produce 100 litres of palm-oil methyl ester using gas-heating (Deepthort 100B). This was later modified to use electrical immersion heaters. Still later, I was asked to design a 5 litre reactor (Deepthort 5B) to optimise the operating procedures in its larger relative. (Incidentally, both reactors were designed to produce the required amount of ester. This means that their actual volume is about 20% greater to safely accommodate the greater volume of oil needed.)

The long-term objective was to provide a reliable design for use by small palm-oil extraction units or cooperatives of small-holders in Thailand.

The Cost

The original "Deepthort" batch reactor was designed in May 2002, was made (at speed) in June 2002 and (quickly) operated in July 2002. It has pretty well been in use (on and off) ever since then. It was fabricated in 5 mm thick 304 stainless steel sheet (the low-cost sort used in water treatment and public toilets) and, with ancillary gear, pumps, tanks, hoses, controls, etc., cost less than US$2000.

The Process

It was envisaged that a simple one-stage transesterification reactor would be required. However, as work progressed, the same reactor was likely to be pushed into service to carry out the acid catalysed saponification of high free-fatty acid oils. So what was needed was a reactor that efficiently contacted methanol with palm-oil in the presence of a liquid catalyst, was simple and safe to operate and would require only minimum maintenance.

While oil-palms are extensively grown in southern Thailand, methanol has to be imported. It was therefore desirable to have a reactor that made efficient use of methanol and had provision for its recovery.

Back view

The Design of 'Deepthort'

Back view

The required reactor volume can be achieved in a number of ways: We already had a conventional squat tank fitted with a stirrer where the methanol was poured in from above.

This was not a very efficient device with respect to methanol utilisation so we decided to get the required volume using a tall vessel fitted with a central stirrer and fed with methanol from below. Because methanol has a lower density than palm-oil, this second geometry maximises the chance of methanol capture as it rises through the warm palm-oil. This geometry also provides a sharper cut-off between the glycerol and the methyl ester after the batch reaction is terminated and so facilitates separation. Thus it is a deep reactor rather than the more conventional shallow one. So "Deepthort" seemed appropriate for another reason.

Published information on the rate of the reaction shows that there are three key stages in the overall reaction, which take time:

- Mixing the methanol/methoxide with the palm oil,

- A fairly rapid reaction to about 80% conversion which needs sufficient methanol but not an excess,

- A slow reaction to about 87% conversion at equilibrium which can be pushed to maybe 97% conversion if sufficient excess methanol is present.

The first mixing constraint can produce a "lag-time" while methanol and palm-oil are pushed into contact. To speed up this process, we placed a paddle-stirrer in the lower half of the reactor. Not much mixing is needed if the methanol is squirted into the hot oil through small holes because the solubility of methanol in oil rises rapidly as the boiling point of methanol is approached: And if the oil happens to be a bit above the boiling point of methanol (64.8 deg C, 148.6 deg F), the hydrostatic pressure in a "deep" reactor keeps the methanol liquid up to about 70 deg C (158 deg F). (Although it may rumble a bit as it vaporises further up the reactor!)

The second stage, which is fairly rapid, produces the peak concentrations of di-glycerides and mono-glycerides within about 10 minutes. If we use the 6:1 molar ratio (25% v/v), there is no great advantage to dumping the methanol in one big addition.

Indeed, there is a good chance that some of it will by-pass the oil altogether and vaporise into the space above the reactor. By adding the methanol slowly over that initial period, we can make sure that just about all of it is contacted. We use a 12-volt electric petrol pump to push in the methanol/methoxide into the feed pipe against the hydrostatic pressure of the reactor contents.

The methanol feed

The feed pipe has five small holes (2 mm diameter) drilled in it to break down the stream of methanol and increase interfacial area between the liquids. This sort of feed pipe is called a "sparger" and is more usually used to blow gases into liquids. The use of a sparger also means that we do not require violent agitation, just gentle mixing inside the reactor. We found that a half horse-power motor is more than sufficient to allow the small paddles to revolve at the 100 rpm that is needed. (We use 12-volt wind screen wiper motors and gears on the 5-litre reactor but that's maybe a tad small for the 100-litre "Deepthort".) The angle of the paddles is reversed on alternate rows so that we get zones of intense mixing. In case the holes in the sparger feed-pipe get blocked, we fitted a screwed end cap to the protruding end.

This cap can be replaced by a hose connection so that compressed air can be applied to the sparger. (So far we have not had to use this feature.)

The methanol pump

The third stage of the reaction is the slowest of the three and takes up to 40 minutes at 60 deg C (140 deg F). This stage requires excess methanol so, ideally, we should have fed in all the methanol after about 15 minutes. We find that our 12-volt petrol pump has an output that depends on suction head as well as delivery head so we have some control over feed rate. A couple of these low-cost units in parallel will also reduce the feed time. (Incidentally, we have had no trouble with diaphragms due to the methanol/methoxide mix which should be good news for all those people who want to use petrol blended with an alcohol in their vehicles.)

There is no mixer in the upper stage of the reactor because the conversion of oil to ester is favoured by reducing the glycerol content. We therefore "encourage" the glycerol to "fall out" of the upper zone.

The design presented shows several "thermowells" which contain glycerol or palm oil. We didn't choose glycerol because it is a by-product of the reaction: we chose it because it is good at transferring heat to the thermocouple which sits in the thermowell. (Palm-oil seems to be just as good, methyl ester also works just fine!) A couple of runs showed us that there was not a big temperature difference between the various thermocouples so, unless we sometimes want to run the reactor half-full, we can leave out all but a couple of the bottom thermowells. (You will need one or two to run the controller on the heat source and to monitor its effectiveness in providing a constant temperature for the reaction.)

A major feature of the design is the provision of a condenser on the vapour outlet from the reactor. This ensures that the reactor is not pressurised and that most of the vapour is condensed and returned to the feed drum. We could make the condensed methanol return directly to the reactor but we chose to measure it and pump it back in with the feed methanol. This condenser also means that we can heat the reactor in a separate operation to recover excess methanol from ester or from glycerol. 6kW of immersion heaters were provided for this purpose and for drying the raw oil. This is excessive for just the reactor duty which can manage on 3kW (just 1 kW of which needs to be controlled by the thermocouple).

Back of the condenser

Side of the condenser

At 60 deg C, most of the methanol is captured by the oil and the glycerol. As a consequence, very little methanol is being condensed out of the vapour during normal operation as a reactor.

Oil is pumped into the reactor using a gear pump. Glycerol and ester are removed from the reactor by gravity using a transparent plastic pipe so that the interface between the two fluids can be detected. To provide access to the drain at the base, the whole reactor is supported on three legs fabricated from 50 mm dia tube which is welded to the shell.

Operation of 'Deepthort' as an Oil Dryer

Oil is pumped into the bottom of the reactor. It can take up to 120 litres unless frothing is a problem. (There are ball valves to seal the inlet and the product lines). The minimum volume is about 20 litres otherwise the heaters are exposed to the air and there is then a risk of explosion. Switch on the stirrer (and set to about 100 rpm to help heat transfer). The heaters (provided they are submerged!) are then switched on and the temperature of the oil raised to 120 deg C (248 deg F). It is then left to cool to about 90 deg C (194 deg F) with the stirrer running. The condenser can be used to collect and remove the water from the system.

Operation of 'Deepthort' as an Acid Catalysed Esterifier

Up to 120 litres of oil are pumped into the bottom of the reactor and the methanol pump started. (There are ball valves to seal the feed lines and the product lines.) Because excess methanol is used in this reaction, the required amount of concentrated sulphuric acid (or phosphoric if you prefer) can be introduced through a screw-plugged hole in the top of the reactor when about half of the methanol has been introduced.

Oil feed

If the reactor is to be used regularly for an acid catalysed esterification, the top thermowell could be replaced with a short open tube entering the vessel at 45 degrees and fitted with a screwed plug. Great care should be taken in handling concentrated acid and a syringe or a pipette should be used to transfer the required amount of acid to the reactor. Spillages should be immediately cleaned up. [Calcium carbonate (limestone powder) can be used for this. Sodium bicarbonate (baking soda) can also be used but spillages on clothes or exposed parts of the body will require copious amounts of water if serious damage is to be avoided. Phosphoric acid is no kinder to human flesh than sulphuric acid. It is not really a safer option!]

Operation of 'Deepthort' as a Transesterifier

This was, of course, the main function of the reactor. Again, oil is fed into the bottom of the reactor using a pump. (There are ball valves to seal the feed lines and the product lines). Switch on the stirrer. The heaters are then switched on and the temperature brought up to the reaction temperature. [Do check that the heater elements are covered with oil before switching on -- we really don't want Big Bang Theory applied to Deepthort.]

Transfer pump

While this is happening, mix up the required amount of methoxide dissolved in the required amount of methanol. (Any of the methods described elsewhere will do just fine!) When the desired reaction temperature has been reached, turn on the cooling water to the condenser and start the methanol feed-pump. Make sure the outlet pipe from the condenser reaches the feed-tank or some other closed container (closed -- not sealed!). Do not submerge the end of the pipe below the methanol liquid level otherwise you will pressurise the reactor and condenser.

When all the methanol has been added (over at least 20 minutes), isolate the methanol feed pipe with the ball-valve and shut down the feed pump. Allow at least 40 minutes for the reaction to complete before turning off the heater. Probably glycerol will have already started to settle out so you can turn off the stirrer and let it complete its settling. We find it is best to discharge the glycerol while it is still warm to keep it liquid so we only wait about 30 - 60 minutes for settling to occur. Usually the interface between glycerol and ester is quite sharp. But if we have any doubts, we put the dodgy material into a covered "slops" drum and let it settle out there. (It must be covered to stop methanol evaporation! When sufficient "slops" has built up in our 200-litre drum, we skim the ester off the top and drain some glycerol out of the bottom to make room for fresh "offspec" material.)

We use the same product outlet valve to gravity-discharge the ester.

Product outlet

We do not clean the reactor before the next transesterification: there is some evidence that small amounts of glycerol and ester can actually reduce the initial lag period by altering the surface tension and "wetting" the fresh oil/methanol mix.

Operation of 'Deepthort' as a Washer

If you are really keen on one-drum clothes-washing machines, you may like to consider "bubble washing" in the reactor.

Firstly, I would suggest that you titrate the oil, suitably dispersed in isopropanol (or methylated spirits if you prefer) against an acid solution. (1 gram of acid in 1 litre of water is a useful concentration.) This tells you how much free caustic is in the oil.

You will probably need to use methyl orange as the indicator because this is a strong acid/strong alkali titration. If you take a 5 ml sample of oil, then the amount of solution which neutralizes it (in millilitres) must be divided by 5 to tell you how many grams of acid are needed to neutralise the alkali in 1 litre of ester. It really doesn't matter what acid you use for the neutralization as long as you use the same one for your titrations. (You could even use citric or acetic acid if you have a cheap source although sulphuric and phosphoric are the most favoured.) The snag with an acid wash is that if you leave the ester in contact with acidified water long enough, you get the reverse esterification reaction occurring with the formation of free fatty acids and methanol. So either wash quickly or use less (that includes none at all!) acid.

The spray tower cooler for the condenser water coolant is made of three cake tins which have been perforated so they cascade water into the drum. The drum is connected to another by a 50 mm diameter pipe and the whole thing is driven by a centrifugal pump with a by-pass valve to adjust flow through the condenser.

Remember that the Deepthort vessel only holds 120 litres. So, with the usual 2:1 wash water:ester ratio, you can put about 60 litres of water into the vessel. If you are going to use an acid wash, add enough to neutralise the caustic in 30 litres of ester before you pump it in.

Now you can introduce compressed air into that sparger pipe so that it bubbles up through the water and cleans the ester. And you still have a 30-litre space in the top of the vessel to disengage the air and hold any foam formed. (Actually, if you get much foam, there was something wrong with your process.) By the way, you'll need a regulator on that compressed air line because it doesn't need much pressure to overcome the hydrostatic pressure. Also you should make absolutely sure that the condenser outlet is clear so that the air can escape! (You will notice that the dimensioned drawings show no restriction, valve, etc. on that outlet line. That is not an oversight.)

Check the pH of the wash water from time to time with a pH meter or pH paper just to see if it climbs to pH 7 or 8 as it removes the soaps and the methoxide. If it does not, you added too much acid. If it goes much higher, then you added too little!

Let the liquid settle and separate. If you intend leaving it overnight, make sure that the pH of the wash water is now greater than about 8. And of course, after separation, you can now heat the ester to 110 deg C (230 deg F) to get rid of any dissolved water.

This we find is not usually necessary because a slight water haze can usually be cleared by just heating the ester to 50 deg C (122 deg F) and letting it settle again. Our daytime ambient temperature is also pretty high at 30 deg C (86 deg F) so your experience may be different.

The spray tower in action

Let me say right now that we have never used Deepthort to wash the ester or to dry it. The unit was designed to do it but we have never bothered. Why? Well we like to see the clarity (or otherwise) of the wash water and the ester above it. We also like to keep water out of our transesterification reactor whenever possible. And it takes up valuable time when the reactor could be used to make more ester. Finally, we don't adjust pH this way because we prefer to add as little acid to the wash water as we can. Washing in a separate drum makes it possible to add any acid needed incrementally while washing is actually taking place.

Recovering Methanol Using 'Deepthort'

It's pretty easy to recover methanol from the ester: Just heat it slowly to about 100 deg C (212 deg F) and condense out the methanol. But much of the methanol is actually held in the glycerol so you don't get a lot back from the ester. Provided you don't let the methanol evaporate by sloppy or uncovered storage, the glycerol stays more or less liquid. But it is a very viscous liquid at room temperature and re-heating it is none too easy. A gear pump can be used to transfer it back into the reactor where it can be slowly heated to about 150 deg C (302 deg F) to drive off the methanol (which, provided you remembered to turn on the water to the condenser, will collect as a liquid. But you had better be quick about draining the methanol-free glycerol out of the reactor or it will solidify in there! And I can assure you from personal experience, it is not easy to get rapidly congealing glycerol out of "Deepthort".)

Currently, we are looking at ways of recovering methanol directly from the glycerol storage tank while it is still close to the reaction temperature. Otherwise, the cost of the heat used in recovering the methanol offsets much of the value of the recycled methanol.

Disclaimer

This versatile piece of equipment can be used for just about every unit operation encountered in making methyl esters of vegetable oils. Knowing the ingenuity of biodieselers, I'm sure it can be used for several things I haven't even thought of! And that is one reason why neither I nor Journey to Forever (and certainly not the Prince of Songkla University!) can take any responsibility for any damage that you do to yourself, your property, your friends, neighbours, their children, their property, boyfriends, dogs, cats, goldfish, chattels, attachments, appendages and whatever else while using it. Like all good developmental technology, the responsibility for safe use depends upon the operator not the designer. And because there is a great variation in oil properties and operator intelligence, I cannot guarantee that it will actually meet any particular requirement. I can assure you that the information is supplied in good faith and based upon personal experience.

The reason for placing this information in the Public Domain is that I have no wish to patent this device. I would prefer that it is freely available to all. In "payment" for my intellectual property, I ask that you quote your source -- JourneyToForever.org (http://journeytoforever.org/) -- when you use the information. I further request that you draw the public nature of this information to the attention of anyone seeking to patent it or to otherwise use it to their own exclusive personal advantage.

Michael Allen

Visiting Professor

Prince of Songkla University

15 August, 2004

Thailand

Blueprints

Complete plans

Large size -- 240kb

Vector-based (scaleable) -- Acrobat file, 104kb

Reactor plans

Large size -- 204kb

Vector-based (scaleable) -- Acrobat file, 60kb

Condenser details

Large size -- 144kb

Vector-based (scaleable) -- Acrobat file, 40kb

Condenser, thermowell, methanol feed pipe

Large size -- 200kb

Vector-based (scaleable) -- Acrobat file, 52kb

Biodiesel processors

Introduction

Scaling up

Hazards

Test-batch mini-processor

Simple 5-gallon processor

Journey to Forever 90-litre processor

The 'Deepthort 100B' Batch Reactor

Ian's vacuum biodiesel processor

Chuck Ranum's biodiesel processor

"Foolproof" method processors

The touchless processor

Joe Street's processor

Continuous reactors

How to make a cone-bottomed processor

Biodiesel technology

Biofuels at Journey to Forever

Biofuels

En español -- Biocombustibles, biodiesel

Biofuels Library

Biofuels supplies and suppliers

Biodiesel

Make your own biodiesel

Mike Pelly's recipe

Two-stage biodiesel process

FOOLPROOF biodiesel process

Biodiesel processors

Biodiesel in Hong Kong

Nitrogen Oxide emissions

Glycerine

Biodiesel resources on the Web

Do diesels have a future?

Vegetable oil yields and characteristics

Washing

Biodiesel and your vehicle

Food or fuel?

Straight vegetable oil as diesel fuel

Ethanol

Ethanol resources on the Web

Is ethanol energy-efficient?