Reprinted from I&EC PROCESS DESIGN & DEVELOPMENT, 1984, 23, 437.

Copyright © 1984 by the American Chemical Society and reprinted by permission of the copyright owner.

Michael R. Ladisch,(1) Marclo Voloch,(2) Juan Hong,(3) Paul Blenkowski(2) and George T. Tsao

Laboratory of Renewable Resources Engineering, Department of Agricultural Engineering, and School of Chemical Engineering, Purdue University, West Lafayette, Indiana 47907

- Laboratory of Renewable Resources Engineering.

- Department of Chemical and Nuclear Engineering, University of Maryland, College Park, MD 20770.

- Laboratory of Renewable Resources Engineering; Department of Chemical and Nuclear Engineering, University of Maryland, College Park, MD 20770.

Ground corn selectively adsorbs water to give anhydrous product from ethanol vapors containing between 1.6 and 50.9% water. An adiabatic corn adsorber system is characterized by formation of a combined wave front (the temperature and concentration waves elute from the column at the same time). Corn is stable under cyclic use when regeneration is carried out with air or N2 at 80 to 120 deg C. The energy required to regenerate the adsorbent is less than 1500 Btu/gal (528 kJ/kg) of anhydrous product obtained from ethanol vapor containing 7.4% water. Anhydrous product also results when water-containing vapors of n-propyl, isopropyl, or tert-butyl alcohol are passed over corn. Corn and other polysaccharide materials have potential as low-cost adsorbents for energy efficient water removal from alcohols.

Introduction

Conventional techniques for separating water from ethanol include low-pressure distillation, azeotropic distillation with pentane, benzene, and diethyl ether, and extractive distillation with gasoline or ethylene glycol (Black, 1980). Low pressure (0.07 atm (Honeywell, 1980)) or third components in these distillation schemes break the azeotrope which forms between ethanol and water at 95.6 wt% ethanol (at atmospheric pressure). Potential methods to obtain anhydrous alcohol also include the adsorption of water on calcium chloride (Noyes, 1923), lime (Noyes, 1923; Pusl, 1933), barium oxide (Smith, 1949), metallic sodium (Smith, 1949), silica gel (Davis and Swearingen, 1931), and biomass materials (Ladisch and Dyck, 1979a; Ladisch et al., 1979b; Ladisch and Tsao, 1982).

Several years ago it was reported that the distillation of ethanol could consume up to 50% of the overall energy used in a typical grain alcohol plant (David et al., 1978; Ghose and Tyagi, 1979). More recently, an improved energy efficiency (Katzen et al., 1980) has been achieved by staging the distillation in a multiple effect configuration. The reported steam consumption of 15 to 20 lb (ca. 15 000 to 20 000 Btu) per gallon of anhydrous alcohol compares favorably to the higher heating value of anhydrous ethanol (liquid) of 84 245 Btu/ gal. This technology appears to be subject to economies of scale.

The combination of distillation followed by adsorption has potential. Distillation requires a disproportionate increase in energy at product concentrations above 92% (by weight) ethanol due to the shape of the equilibrium curve which, in effect, controls the minimum reflux (i.e., minimum energy required) for a thermally saturated, 12% ethanol feed (Ladisch and Dyck, 1979a). Consequently, stopping the distillation at 92% or less combined with an appropriate adsorption technique to obtain anhydrous product may reduce the overall energy requirements as compared to traditional distillation approaches (Ladisch and Dyck, 1979a; Ladisch et al., 1979b; Voloch et al., 1980). In this context, characteristics of cornmeal for adsorption of water are discussed.

Background

The adsorption and desorption properties of starch and cornmeal at temperatures below 50 deg C with respect to water and ethanol, separately, are known (Do-sup and Pfost, 1967; Bushuk and Winkler, 1957; Rodriguez-Arias et al., 1963). Ethanol adsorbs at a slower rate and to a smaller extent than water at 35 deg C (Gupta and Bhatia, 1969). At 80 to 100 deg C ethanol adsorption is minimal relative to water (Hong et al., 1982). The observed water isotherms (per the definition of Brunauer, 1943) are type II and show hysteresis in which the equilibrium vapor phase concentration is higher on sorption than desorption for starch (Gupta and Bhatia, 1969). Under isothermal conditions, an adsorbent having a type II isotherm will show distinct breakthrough patterns at local equilibrium conditions (Goldstein, 1953; Tudge, 1961). Small bore columns (4.63 mm i.d.), where isothermal conditions can be attained, give such characteristic patterns which are useful for comparing sorption properties of different polysaccharides at temperatures between 80 and 100 deg C and pressures above atmospheric (Hong et al., 1982).

Adiabatic conditions result when larger diameter columns are used. Methods for modeling an adiabatic adsorber include those of Rhee et al. (1970a, 1970b, 1974), Leavit (1962), and Cooney (1974). Pan and Basmadji (1967, 1970, 1971) report methods for rapid analysis for several cases based on constant pattern profiles and equilibrium theory. The approach of Pan and Basmadjian (1970) was used in interpreting our data.

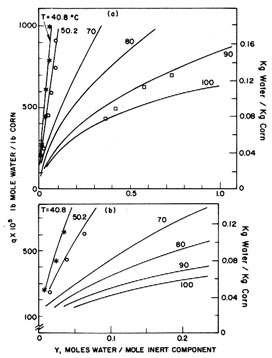

Figure 1. Equilibrium isotherms for yellow dent corn at atmospheric pressure. Solid lines are based on equation of Henderson (1950) (*), (o) data of Bushuk and Winkler (1957); (sq) data of this work (runs 8, 9, 11, 13, in Table II).

Isotherms for water adsorption at 40 to 100 deg C were estimated by using Henderson's (1952) equation

![]()

The relative humidity (r.h.) values were converted to a weight basis using psychometric charts and then to mole ratios of water:air. The calculated isotherms (Figure 1) at 40.8 and 50.2 deg C follow the data of Bushuk and Winkler (1957) for starch when K = 1.10 X 10-5 and n = 1.90 (from Henderson, 1952). Figure lb gives expanded isotherms at mole fractions of up to 0.24. This is the region of primary interest for water/ethanol separations by adsorption. Although these isotherms represent an extrapolation, they are a useful tool in interpreting general trends in our data. The major criterion for their use is that ethanol, like air, does not significantly adsorb at the conditions examined. This is the case at temperatures of 80 deg C and higher (Hong et al., 1982).

Experimental Procedures

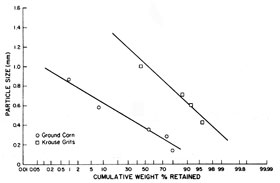

Adsorbent. The adsorbent was cornmeal with the size distribution as shown in Figure 2. The cornmeal was prepared from whole grain field corn (Lafayette, IN) ground through a 20-mesh screen using a Wiley Mill (Arthur Thomas Co., Philadelphia, PA). In selected runs, corn grits (Krause Milling Co., Milwaukee, WI) were also used (see Figure 2 for particle size distribution).

Figure 2. Particle size distribution of ground corn and corn grits.

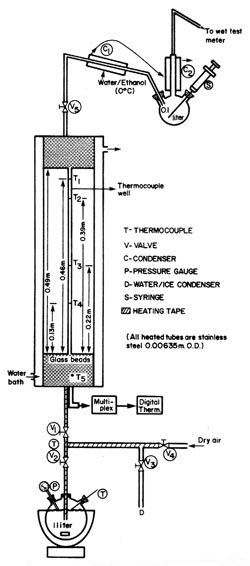

Bench-Scale Adsorber. The bench-scale adsorber apparatus is shown in Figure 3. The cornmeal (156 g) in this adsorber (dimensions, 25.4 mm i.d. X 49 cm bed depth) was dried overnight prior to the first run by passing air upflow at 88 to 90 deg C. This apparatus was designed to determine experimentally the adsorption characteristics only. The column wall temperature was maintained at the initial bed temperature during a run by circulating hot water through the jacket.

In a typical run, vapor was boiled up from a flask (1 L volume) surrounded by an electric heating mantle. Heat input was controlled by a variable transformer. Valve V2 was manually controlled to keep boiler pressure, and hence, flow rate, constant at constant heat input to the flask.Vapor passed through valves V2 and V3. The water content of condensed vapor was determined by using an automated water analyzer (Aquatest IV, Photovolt, NY) prior to a run. During a run, vapor passed through V2 and V1, the column, and then V5. The outlet stream was condensed using an ethanol-water mixture at 0 deg C as a cooling medium (Cl). The condensate in the receiving flask was removed about every 120 s and its volume and water composition were determined. The water adsorbed on the corn was calculated by difference. The average condensate flow rate was ca. 3.4 X 10-5 L/s (2 mL/min) of liquid. The bed was dried upflow, between runs, for several hours with an excess quantity of hot air at a flow rate of 0.0083 to 0.0167 L/s (0.5 to 1.0 L/min) as measured at 25 deg C and 101 KPa (1 atm).

Figure 3. Schematic diagram of bench-scale adsorber. Jacket insulated with 1-in. fiberglass (not shown).

It should be noted that introduction of a feed into the column below its dewpoint may cause the adsorbent to swell, with the adsorbent eventually clogging the column. Consequently, care was taken to assure a vapor feed to the adsorber.

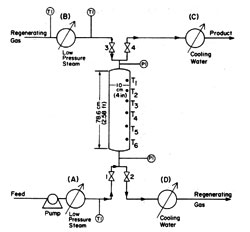

Pilot-Scale Adsorber. Scale-up runs were carried out with a 10 cm (4 in.) i.d. X 78.6 cm (2.58 ft) high adsorber constructed of copper and packed with 4.54 kg (dry weight) of cornmeal (Figure 4). The column insulation was 2.54 cm thick. The heat exchangers (low pressure steam on shell side) served to heat and vaporize a liquid ethanol/ water feed (A) and heat the regenerating gas (either N2 or air) to 80 to 90 deg C) (b). Condensers (water at 55 to 60 deg F on shell side) served to condense and cool the product (C) or cool the outlet regenerating gas stream (D). Thermocouples were placed in a thermowell (located about 2.54 cm from the wall) at (T6) 7.6 cm; (T5) 20 cm; (T4) 36.6 cm; (T3) 48.4 cm; (T2) 60.7 cm; and (Tl) 70.9 cm from the bottom of the column.

The corn adsorbent used here was grits. The grits were charged at 12% moisture and then dried by passing air heated to 80-90 deg C, over the bed for 12-14 h at a velocity of 0.5 to 1 ft/s (0.15 to 0.3 m/s). Before each adsorption run, the bed is heated to the desired temperature with hot air (80 to 100 deg C) having a 14.4 deg C wet bulb temperature.The air is then flushed out with N2. A run consisted of: (1) closing valves 2 and 3, opening valves 1 and 4, and turning on the metering pump; (2) vaporizing the ethanol/water mixture in heat exchanger A and then passing the vapor through the bed and collecting samples of condensed product for water analysis; and (3) upon completion of the adsorption cycle, closing valves 1 and 4 and opening valves 3 and 2 to carry out downflow regeneration by first flushing with N2 to remove ethanol vapors and avoid a flammable gas mixture (Zabetakis, 1965), and then using air preheated to 80-90 deg C. This apparatus gave some practical data on the operational characteristics of the adsorbent.

Figure 4. Diagram of adiabatic pilot scale adsorber.

Figure 4. Diagram of adiabatic pilot scale adsorber.

Results and Discussion

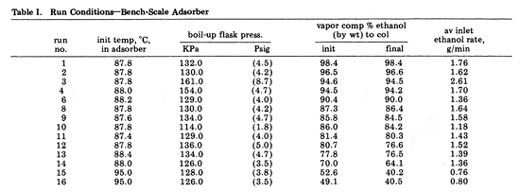

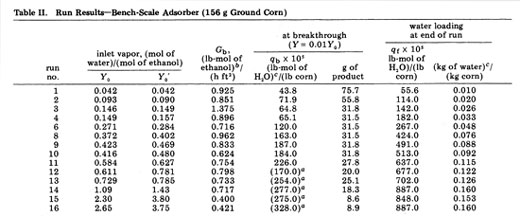

Adsorbent Capacity. Ethanol vapors of 49.1% (Yo = 2.65) to 98.4 wt % (Yo = 0.042) were passed over cornmeal in the bench-scale column (Figure 3) with run conditions as given in Table I. The back-pressure on the boil-up flask was several psig to allow control of the vapor flow rate, as mentioned previously. The pressure drop across the column itself was negligible.

a Values are approximate because inlet vapor composition changes significantly between start of run and breakthrough as well as between start of run and end of run. Calculations based on values of yo.

b (1 lb-mol of ethanol)/(h ft2) 0.0625 kg/(ml s).

c Calculated from the mixing cup average of water content for total product collected.

Vapor rates are expressed on the basis of ethanol throughput (Table II), with breakthrough being defined as Y = 0.01 Yo (molar basis). A product of 99.6% by weight (or higher) of ethanol was initially obtained in all runs (Table II). Changes in the inlet vapor composition were small (compare initial and final inlet vapor compositions in Tables I and II at ca. 80% or greater ethanol composition. Below this ethanol content, changes in inlet vapor composition of up to 25% (relative weight basis) were observed during the course of a run due to partial fractionation occurring in the boil-up flask.

The water loadings at breakthrough and at the end of an experiment are summarized in Table II. In runs 8, 9, 11, and 13, where Y begins to approach Yo near the end of the run, the values of qf approach those of the equilibrium curve at T = 90 deg C (see Figure 1). Thermocouples placed in the adsorbent bed show that the heat of adsorption is eventually carried away, with the column temperature approaching its initial (jacket) temperature at long run times. Hence, the observed loading at the end of the run appears to be close to equilibrium bed loading at the respective final bed temperature. Other experiments carried out at initial bed and inlet vapor temperatures of 78.8 deg C gave a 35% increased loading above that obtained at 88 to 90 deg C. This is again consistent with the general trend indicated by the equilibrium data. Bed capacity at equilibrium will be maximized by using a temperature as close as possible to (but still above) the dew point of the inlet vapor.

Figure 5. Temperature profiles during adsorption in bench-scale adsorber (for apparatus shown in Figure 3).

Figure 5. Temperature profiles during adsorption in bench-scale adsorber (for apparatus shown in Figure 3).

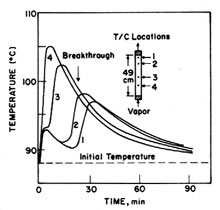

Temperature and Concentration Profiles. Significant temperature transients occur during the course of a run. An example is given in Figure 5. The temperature rises occur as described by Pan and Basmadjian (1967, p 287). Of particular interest is the temperature profile observed near the bed outlet (curve 1 in Figure 5) which consists of a slight temperature rise followed by a large temperature rise.

The temperature and water content near the bed exit (position 1 in Figure 5) as a function of time is given for runs 1, 4, 8, and 11 in Figure 6. The first temperature peak occurs within 2 to 3 min after the run is initiated. We do not currently have sufficient data to explain this phenomenon, although some possibilities are given by Pan and Basmadjian (1971). The second temperature wave in Figure 6 corresponds to the arrival of the concentration front.

Figure 6. Temperature and concentration profiles for bench-scale adsorber (for apparatus shown in Figure 3).

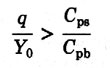

According to Pan and Basmadjian (1967,1970,1971) and Basmadjian (1980), a pure thermal wave is possible (but not necessary) in our system if

Following the example of Basmadjian (1980), calculations were done for the temperatures of 80, 90, and 100 deg C at values of Y (= Yo) of 0.729, 0.584, 0.372, 0.149, and 0.042 with q (= q*) determined from the equilibrium curves in Figure 1. The values of Cpb were: 19.5 Btu (lb-mol of ethanol)-1 deg F-1 (= 0.547 kJ kg-1 K-1); 19.83 (= 0.556 kJ kg-1 K-1); and 20.15 (= 0.565 kJ kg-1 K-1), at 80, 90, and 100 deg C, respectively (Anderson and Wenzel, 1961). Since the values of Cps change with water loading (see Figure 7b - data for yellow dent corn from Kazarian and Hall, 1965), Cps was determined individually for each value of q. Figure 7a gives the results of these calculations which show that: (1) at ethanol concentrations below 87.3% a combined wavefront is predicted; and (2) a pure thermal wave may be possible depending on initial bed temperature and moisture content and inlet vapor composition. The initial temperatures (88 deg C) and inlet vapor compositions of the runs 8 (Yo = 0.372) and 11 (Yo = 0.548) in Figures 6c and 6d result in prediction of a combined wavefront while run 4 (Yo = 0.149) is predicted to be a borderline case. These calculated predictions (shown graphically in Figure 7a) are consistent with run data which show the temperature and concentration waves to come out together (Figures 6b to 6d).

A pure thermal wave is possible for Yo = 0.042 at 88 deg C (Figure 6a). The profiles for this case (Figure 6a) do not clearly show such a separation. It is possible the bed height may be too short for a fully developed separation to be observed although heat loss from the bench-scale adsorber would favor a separation of temperature and concentration waves (Pan and Basmadjian, 1970).

When the pilot scale, adiabatic adsorber (Figure 4) was run at an initial bed temperature of 81 ± 3 deg C, a combined wave front occurred for Gb = 0.65, and Yo = 0.262 (Figure 8). In this case the bed was dried (regenerated) with air having a water:air molar ratio of 0.016. Consequently, the corn, after regeneration, retained a small amount of water (estimated at 2 to 4% - see Figure 1). An initial bed loading of water will preclude the formation of a thermal wave (Pan and Basmadjian, 1971) although a substantially water-free product can still be obtained.

Figure 7. (a) Plot of Cps/Cpb vs. q/Y1 illustrating conditions at which combined wavefront would be expected. (b) Plot of Cps as function of moisture loading (Kazurian and Hall, 1965).

Energy Requirements. The heat given off during adsorption is stored by the corn adsorbent. In runs with the apparatus shown in Figure 4, energy balances show that between 80 and 92% of the heat of adsorption will be retained in the bed if adsorption is stopped when the concentration wave begins to leave the column. Hence, it is desirable to adsorb upflow and regenerate by passing gas downflow, thus making use of some of the heat of adsorption stored at the upper part of the bed to drive off adsorbed water from the bottom of the bed. A multi-bed unit (based on the design indicated in Figure 4) having a nominal capacity of 3 to 12 kg of product/h has already been tested in a farm-scale plant over a three-month period. This unit was packed with 18 kg of corn grits. It was found to perform satisfactorily in producing 199.8 proof or higher ethanol. The overall energy required is 5000 Btu/gal of anhydrous product (= 1760 kJ/kg) starting from a liquid feed of 92% (by weight) ethanol at ambient temperature. This includes the energy required to heat the feed from ambient and vaporize it, the energy needed to heat the regenerating air from ambient to an inlet temperature of 95 deg C, and heat losses from the overall system. When a vapor is fed directly to the unit, less than 1500 Btu/gal (= 530 kJ/kg) is needed.Passing the regenerating gas in a direction cocurrent to that for adsorption is not recommended for a practical unit. Passage of the regenerating gas in this manner causes water to be carried from a more saturated portion of the bed to a less saturated one. Hence, the water can be partially readsorbed on the corn before leaving the column. This increases the time required for regeneration, and also the energy required, since the heat of adsorption stored in the bed is not efficiently utilized during desorption.

If a heat of adsorption of less than 1400 Btu/lb of water (3254 kJ/kg) (Rodriquez-Arias et al., 1963) is assumed, the minimum calculated energy requirement for regeneration is less than 740 Btu/gal of anhydrous product (260 kJ/kg) for an inlet ethanol feed containing 7.4% (by weight) water. The energy actually used was double at 1500 Btu/gal. One contributing factor for the higher energy use is that the heat content in the regenerating gas, equivalent to the temperature difference between ambient (20 deg C) and the outlet gas temperature (75-80 deg C), is not used. If heat exchangers were added to recover some of this heat, the net energy required would be less.

Figure 8. Temperature and concentration profiles for pilot scale adsorber (for apparatus shown in Figure 4).

Adsorbent Stability. A bench-scale adsorber of bed dimensions of 2.5 cm. (i.d.) X 45 cm bed depth was packed with 179.8 g of corn grits and run for three months in an apparatus similar to the one shown in Figure 3 at temperature ranges discussed previously. Adsorption was carried out upflow using ethanol vapor ranging from 88 to 95% (by weight) composition. Each adsorption cycle was followed by downflow desorption with either hot air or N2 as a regenerating gas. During this time over 85 cycles of adsorption/ desorption were carried out. There was no measurable change in the adsorption characteristics of the corn. This gives a first indication that corn is a stable adsorbent under cyclic use.

Dehydration of Other Alcohols. Anhydrous product was also obtained when vapors of 71.5% n-propyl alcohol (To = 97.4 0Q, 86.2% isopropyl alcohol (To = 85.8 0Q, and 88.9% tert-butyl alcohol (To = 87.6 deg C) were passed over ground corn in 2.5 cm i.d. X 45 cm high bed. The preliminary data indicated that corn or other polysaccharide materials may find a use for dehydrating other industrially important alcohols. Applications involving other water/organic mixtures could also be postulated.

Conclusions

Corn is a potentially attractive adsorbent for removing water from alcohols. Corn is inexpensive (5 to 10c/lb), operates at relatively mild conditions (close to atmospheric pressure, and 80 to 110 deg C), and provides an energy efficient means to remove water from ethanol.

The adsorption of water from water/ethanol mixtures over ground corn or corn grits indicates that a combined wavefront is formed. Although a pure thermal wave is possible, the necessary conditions are not satisfied for the ranges of ethanol compositions, temperatures, and initial adsorbent moistures examined in this work.

Other polysaccharide containing materials are also indicated to be potential adsorbents. Starch, hemicellulose, and cellulose have similar water sorption properties (Hong et al., 1982). Hence, depending on the application, a variety of polysaccharide adsorbents including cellulose, carboxymethyl cellulose, cornmeal, corncobs, wheat straw, bagasse, starch, xylan, wood chips, other grains, and mixtures of such materials could be considered (Ladisch and Tsao, 1982).

Under laboratory and pilot plant conditions, cornmeal or associated corn products are stable adsorbents. We speculate that cellulosic materials will also exhibit similar stability. In the event that capacity were lost for corn over a period of time, the cornmeal could still be used to make fermentation-derived ethanol.

Cornmeal and other polysaccharides are attractive for small and medium scale production facilities where other separation schemes do not seem to be appropriate. A need apparently exists for small-scale (ca. 3.8 X 10m L/year) adsorption processes for removing water from organic azeotropes (Garg and Ausikaitis, 1983). Polysaccharide adsorbents appear to have potential in practical schemes for energy-efficient water removal from alcohol.

Acknowledgments

This work was supported by USDA Grant Numbers 901-15-112 and 59-2181-0-2-102-0. We would also like to acknowledge the excellent technical assistance of Joan Deerwester in performing the stability studies, George Woodruff and Mark Brewer for their work in building the many experimental apparatus required to carry out this work, and Robert Neuman and Elaine Caldbeck for analytical assistance. One of the authors (M.R.L.) would also like to thank Dr. Myrl Miller (Terre Haute, IN) for his many helpful discussions and comments during the writing of this manuscript.

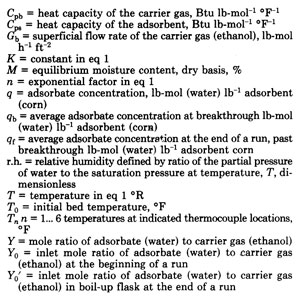

Nomenclature

Registry No. Ethanol, 64-17-5; n-propyl alcohol, 71-23-8; isopropyl alcohol, 67-63-0; tert-butyl alcohol, 75-65-0.

Literature Cited

Anderson, L. B.; Wenzel, L. A. "Introduction to Chemical Engineering", McGraw-Hill: New York, 1961; pp 350.

Basmadjian, D. Ind. Eng. Chem. Process Des. Dev. 1980, 19, 137.

Black, C. Chem. Eng. Prog. 1980, 76(9), 78.

Brunauer, S. "The Adsorption of Gases and Vapor"; Princeton University Press: Princeton, NJ, 1943.

Bushuk, W.; Winkler, C. A. Cer. Chem. 1957, 34, 87.

Cooney, D. 0. Ind. Eng. Chem. P~,ocess Des. Dev. 1974, 13(4), 368.

David, M. L.; Hammaker, G. S.; Buzenberg, R. J.; Wagner, J. P.; "Gasohol Economic Feasibility Study", Dev. Planning and Res. Assoc., Inc.; Manhattan, KS, 1978.

Davis, H. M.; Swearingen, C. E. J. Phys. Chem. 1931, 35, 1308.

Do-Sup, C.; Pfost, H. B. Trans. ASAE 1967, 10, 549.

Garg, D. R.; Auskiaitus, J. P. Chem. Eng. Prog. 1983, 79(4), 60.

Ghose, T. K.; Tyagi, R. D. Biotechnol. Bioeng. 1979, 21, 1387.

Goldstein, S. F. R. S. Proc. R. Soc. London, Ser. A 1953, 219, 171.

Gupta, S. L.; Bhatia, R. K. S. Indian J. Chem. 1989, 7, 1231.

Henderson, S. M. Agric. Eng. 1952, 33, 29.

Honeywell "Small-Scale Ethanol Plant Control Activities", Roseville, MN, No. 80154, 17, May 1980.

Hong, J.; Voloch, M.; Ladisch, M. R.; Tsao, G. T. Biotechnol. Bioeng. 1982, 24,725.

Katzen, R.; Ackley, W. R.; Moon, G. D.; Messick, J. R.; Bruch, B. F.; Kavpisch, D. F. "Low Energy Distillation Systems", 180th National Meeting of the American Chemical Society, Las Vegas, NV, 1980.

Kazarian, E. A.; Hall, C. W. Trans. ASAE 1985, 8, 33-37.

Ladisch, M. R.; Dyck, K. K. Science 1979a, 205, 898.

Ladisch, M. R.; Voloch, M.; Dyck, K. K.; Allen, J. "Energy Efficient Dehydration of Ethanol"; 178th National Meeting of the American Chemical Society, Washington, DC, 1979b; MICR Div.

Ladisch, M. R.; Tsao, G. T. U.S. Patent 4 345 973, Aug 24, 1982.

Leavitt, F. W. Chem. Eng. Prog. 1962, 58(8), 54.

Noyes, W. A. J. Am. Chem. Soc. 1923, 215, 857.

Pan, C-Y.; Basmadjian, D. Chem. Eng. Sci. 1987, 22, 285.

Pan, C-Y.; Basmadjian, D. Chem. Eng. Sci. 1971, 26, 45.

Pan, C-Y.; Basmadjian, D. Chem. Eng. Sci. 1970, 25, 1653.

Pusl, R. Int. Sugar J. 1933, 266.

Rhee, H-K.; Amundson, N. R. Chem. Eng. J. 1970a, 1, 241.

Rhee, H-K.; Heerolt, E. D.; Amundson, N. R. Chem. Eng. J. 1970b, 1, 279.

Rhee, H-K.; Amundson, N. R. Chem. Eng. Sci. 1974, 29, 2049.

Rodriguez-Arias, J.; Hall, w. w.; Bakker-Arkema, F. W. Cer. Chem. 1963, 40,676.

Smith, F. G. Ind. Eng. Chem. Anal. Ed. 1949, 7, 72.

Tudge, A. P. Can. J. Phys. 1961, 39, 1600.

Voloch, M.; Hong, J.; Ladisch, M. R. "Dehydration of Ethanol Using Cornmeal as an Adsorbent"; MICR Div., 180th National Meeting of the American Chemical Society, Las Vegas, NV, 1980.

Zabetakis, M. R. "Flammability Characteristics of Combustible Gases and Vapors"; Bulletin 627, Bureau of Mines: Pittsburg, PA, 1965.

Received for review November 9, 1981

Revised manuscript received July 18, 1983

Accepted September 8, 1983

Biofuels

Biofuels Library

Biofuels supplies and suppliers

Biodiesel

Make your own biodiesel

Mike Pelly's recipe

Two-stage biodiesel process

FOOLPROOF biodiesel process

Biodiesel processors

Biodiesel in Hong Kong

Nitrogen Oxide emissions

Glycerine

Biodiesel resources on the Web

Do diesels have a future?

Vegetable oil yields and characteristics

Washing

Biodiesel and your vehicle

Food or fuel?

Straight vegetable oil as diesel fuel

Ethanol

Ethanol resources on the Web

Is ethanol energy-efficient?