Chapter 15

SOLAR STILLS

GENERAL DISCUSSION

Solar stills can be simple or elaborate. The solar analogy to a simple pot still is easy to construct and operate. Solar stills that incorporate stripping and reflux sections are also possible, but they are difficult to operate without sophisticated instrumentation and controls. This is because there is a delicate balance between temperature, feed rates, and the amount of vapor in the column. The slightest variation in the input of solar radiant energy will destroy this balance. To operate complex solar stills, all of the variables must be sensed and controlled within very close tolerances. This, unfortunately, means expensive electronic sensors, controls and valves. The overall efficiency of a complex solar still is low and, to offset the cost of instrumentation, the still must be very large.

It is usually better, for larger installations, to use solar power indirectly. For example, a solar installation could be used to preheat the water used for cooking or a solar boiler could be used to supplement a regular boiler for the production of steam.

Simple solar stills have the disadvantage of producing low proof alcohol. However, they are entirely adequate when used to produce fuel for an injection system. An example of a simple fermentation set-up and solar still to produce fuel for an alcohol injected engine is described in Chapter 17. In this application, the solar still makes a lot of sense.

PRINCIPLE OF OPERATION

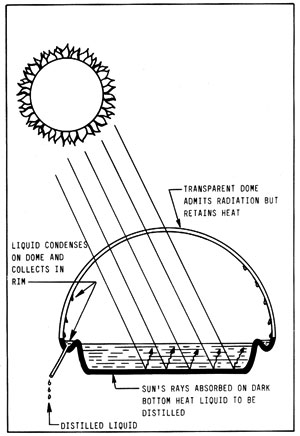

Figure 15-1: BASIC SOLAR STILL

Figure 15-1 illustrates a solar still of the type used in survival gear to distill fresh water from sea water. The sun's rays pass freely through the transparent dome and are absorbed by the dark bottom of the still. The Iiquid in the bottom of the still is heated. Vapors rise, contact the inside of the transparent dome (which remains relatively cool), and condense. The distilled liquid collects in the trough around the rim and is collected through the attached tube.

The still illustrated could just as easily distill alcohol as water. Such stills are available from various suppliers and are fairly inexpensive. However, before purchasing one of these units make sure that the alcohol vapors will not damage whatever plastic is used in the still's construction.

CONSTRUCTION OF SOLAR STILLS

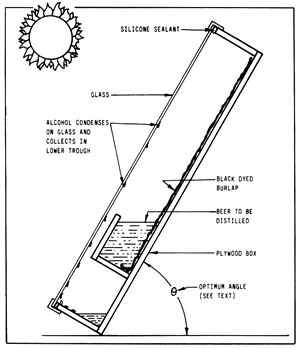

Figure 15-2: PASSIVE SOLAR STILL

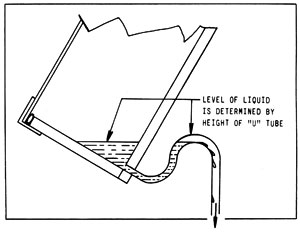

Figure 15-2 shows a cross section of an easily constructed solar still. The box is made of plywood and is about 6 inches deep. The overall height is 2-3 feet. It can be constructed in any convenient length. It is important that the box be vapor tight. Otherwise, the alcohol vapors will escape. Therefore, the inside of the box should be sealed and painted with flat black, chemical resistant, epoxy paint. The glazing should be sealed with a gasket of silicone. A cheaper alternative to glass is translucent fiberglass used in the construction of greenhouses. It is available from most building supply houses in rolls that are 48 inches wide. A valve should be provided to fill and drain the beer trough. The drain opening in the lower alcohol trough must be left open to relieve internal pressure. To prevent uncondensed vapor loss, a simple "U" trap, as illustrated in Figure 15-3, can be installed. The optimum angle for the box as far as the sun is concerned is your latitude plus 15 deg in the winter and minus 15 deg in the summer. In the spring and fall the optimum angle is equal to your latitude.

Figure 15-3: VAPOR TRAP DRAIN

In operation, the beer travels up the black-dyed burlap by capillary action, the alcohol evaporates, condenses on the glass, and collects in the lower trough. The temperature in the box is self-regulating or "passive" because as the box heats up, more alcohol will evaporate. This has a cooling effect. Conversely, if the temperature in the box drops, less alcohol will evaporate, and the temperature will rise. The vapor temperature inside the box should, therefore, remain relatively stable. Typically, the initial temperature will be about 175 deg F. and the proof of the distillate will be about 100-120, depending on the alcohol concentration of the beer. As the alcohol is removed from the beer, the temperature inside the tank will rise and the proof of the alcohol collected will decrease. Therefore, after about 1/2 to 2/3 of the alcohol has been collected, the distillate can be run into a second container for redistillation with the next run.

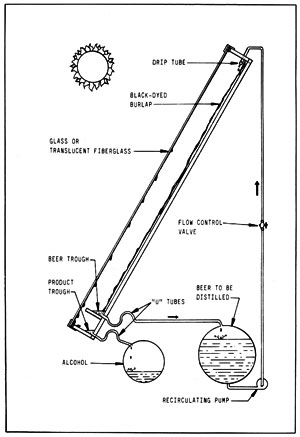

With slight modification the still in Figure 15-2 can be converted from passive batch operation to a more or less continuous operation. A drip tube is installed across the top of the still instead of the beer flowing up the burlap by capillary action, it is allowed to drip down the burlap from above. Figure 15-4 shows a solar still set up for this type of operation. Notice that the height of the still is much greater, about 8 feet. The object is to have all of the alcohol evaporated from the beer by the time it reaches the lower trough. This is not always possible. Therefore, some means of recirculating the beer usually must be provided. Control of the temperature within the still is no longer completely "passive". To a greater extent, it must be "actively" controlled by adjusting the flow rate of the beer. An increased flow rate will lower the temperature inside the box and a reduced rate will raise the temperature. An alternate to controlling the flow rate would be to install louvers or a shade, activated by a thermal sensor, to control internal temperature. The closer the temperature to 173 deg F., the higher the proof of the alcohol. Because the sun's energy is not consistent, some means of automatically controlling the flow rate to maintain optimum temperature is almost mandatory.

Figure 15-4: ACTIVE SOLAR STILL

The passive system has the advantage of being self-regulating as far as temperature is concerned and the disadvantage of producing lower and lower proof as the distillation continues. Because of the fixed volume of the beer trough, it can only process a limited amount of beer at one time. The active system, if properly regulated, is capable of a higher overall proof on the first run and, with a recirculating tank, can process a larger amount of beer. It has the disadvantage of requiring active control of the internal still temperature.

Both stills produce a high enough proof for injection systems. However, if the fuel is to be burned in place of gasoline, the alcohol must be redistilled to achieve an acceptable proof. There is no reason, however, why several stills can not be connected in series with the product from the first being fed to the second, and so on. Also, although overall efficiency is low, the energy from the sun is "free" and stills of this design can be built as large as desired.

Chapter Index

Chapter 1 AN OVERVIEW

Chapter 2 BASIC FUEL THEORY

Chapter 3 UTILIZATION OF ALCOHOL FUELS

Chapter 4 ETHANOL PRODUCTION - GENERAL DISCUSSION

Chapter 5 PROCESSING STEPS COMMON TO ALL MATERIALS

Chapter 6 PROCESSING STEPS SPECIFIC TO SACCHARINE MATERIALS

Chapter 7 PROCESSING STEPS SPECIFIC TO STARCHY MATERIALS

Chapter 8 PROCESSING STEPS SPECIFIC TO CELLULOSE MATERIALS

Chapter 9 YEAST AND FERMENTATION

Chapter 10 INDIVIDUAL RAW MATERIALS

Chapter 11 DISTILLATION

Chapter 12 DRYING THE ALCOHOL

Chapter 13 MASHING AND FERMENTATION EQUIPMENT

Chapter 14 DISTILLATION EQUIPMENT

Chapter 15 SOLAR STILLS

Chapter 16 GOVERNMENT REGULATIONS -- chapter omitted, the information is outdated

Chapter 17 PUTTING IT ALL TOGETHER

Chapter 18 THE FUTURE

Biofuels

Biofuels Library

Biofuels supplies and suppliers

Biodiesel

Make your own biodiesel

Mike Pelly's recipe

Two-stage biodiesel process

FOOLPROOF biodiesel process

Biodiesel processors

Biodiesel in Hong Kong

Nitrogen Oxide emissions

Glycerine

Biodiesel resources on the Web

Do diesels have a future?

Vegetable oil yields and characteristics

Washing

Biodiesel and your vehicle

Food or fuel?

Straight vegetable oil as diesel fuel

Ethanol

Ethanol resources on the Web

Is ethanol energy-efficient?